Design and compilation of the total plant with guaranteed lowest Specific Power and Thermal consumption compared to any other technology available in the Global cement Market.

Starts from the responsible citizen to dispose the garbage in 3 separate bins. MCD garbage Van picks the garbage separately to avoid a mix of

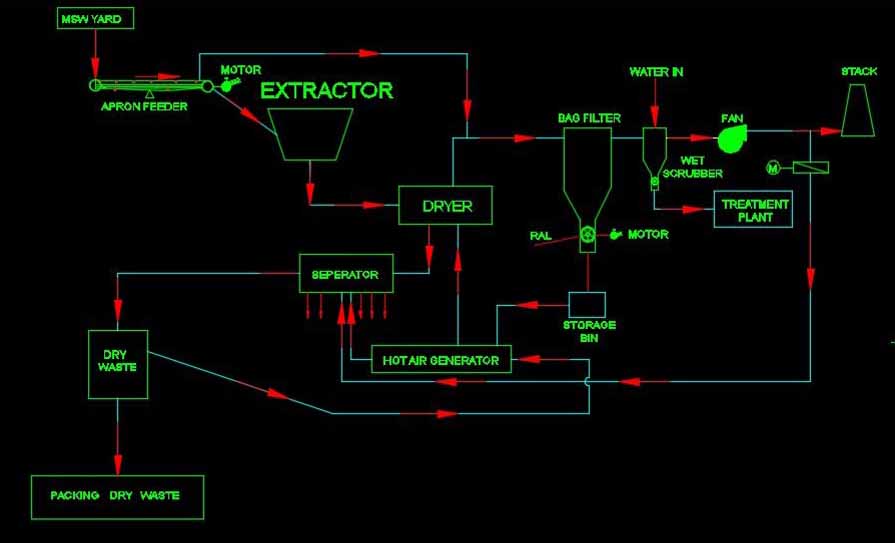

The waste is :

NOTE: This is one of the only economical way to reuse 100% waste without negatively effect to the atmosphere

Below are the list of projects that BQB is willing to take up as Turnkey:

During Execution of Turnkey Projects, we ensure followings: